This China Wholesale High-performance vector inverter is based on a DSP control system, inside PLC,adopts vector control technology, and is combined with various protection methods. It can be used for asynchronous motors to improve their driving performance. It integrates position, speed, and torque control, supports customer secondary development, meets personalized and industry needs, is flexible in application, and has stable performance.USE V/F AND VECTOR CONTROL MODEL, SUITABLE FOR WATER PUMP ,FAN,AIR COMPRESSOR,TEXTILE MACHINE MORE INDUSTRY APPLICATION.

GOOD QUALITY AND EASY OPERATION WITH THE BEST PRICE ,RECEIVED GOOD COMMENTS FROM END USER ALL OVER THE WORLD

Main functions of High-performance V/F vector inverter.

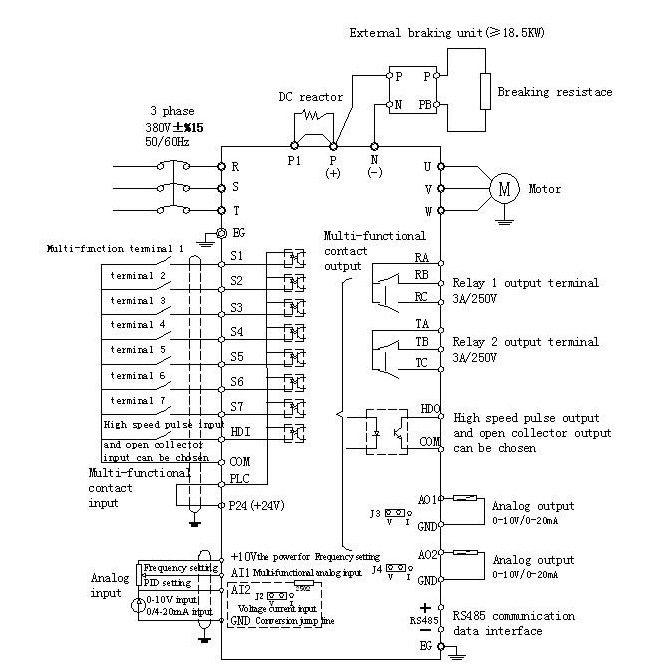

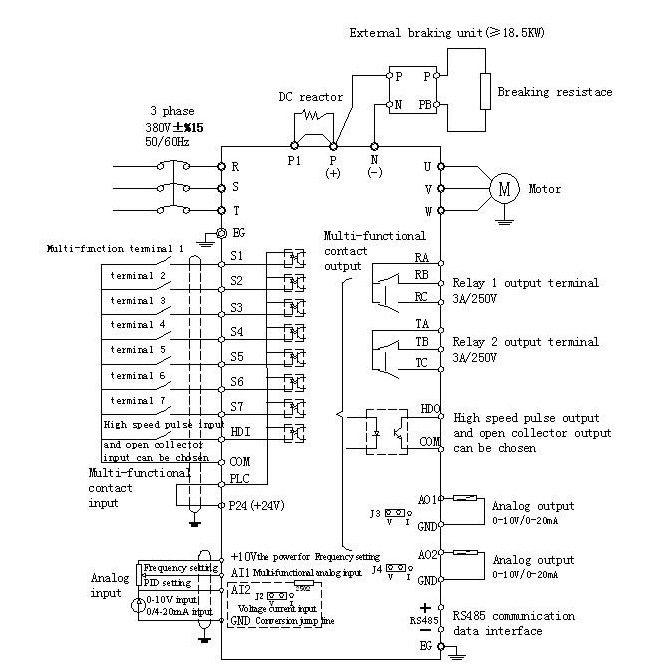

1.Three control modes: without PG vector (SVC), V/F control, and torque control;

2.Starting torque: without PG vector control: 0.5Hz/150% (SVC);

3.18.5kW-90kW inverter built-in DC reactor to improve input power factor and increaseoverall efficiency and stability;

4.Internal brake unit with every specification 0.75-15kW, so that the braking resister can be connected directlyfor a quick stop;

5.16-steps simple PLC, multi-speed control, and PID control

6.Supporting multi-frequency installation methods: digital setup, analog quantity setup, PID setup, and communication setup;

7.Supports starting and stopping DC brake;

8.The input and output terminals may be freely programmed, so users may combine a variety of operating modes as needed;

9.Equipped with jump frequency control which prevents mechanical resonance and makes the system more stable and reliable;

10.Equipped with instantaneous power failure non-outage capability;

11.Equipped with sleep-wake delay installation capability;

12.Equipped with over-torque detection;chf 100a invt inverter.

13.Variety of maximum frequency setting source options;

14.Equipped with a bidirectional shift key , which enables users to use the shift key to view real-time parameters;

15.Rotation speed tracking re-start function: allowing rotating machinery to be started smoothly and without any shocks.

16.overload protection ,over current protection

Main advantage:

1. Vector control

2. 0.4-37KW standard built-in brake unit

3. Support common DC bus scheme

4. Support multiple encoding options

5. Integrateed position control

6. Integrated speed control

7. Integrated torque control

8. Closed loop vector control 0HZ 200% torque out

9. Standard RS485 communication control

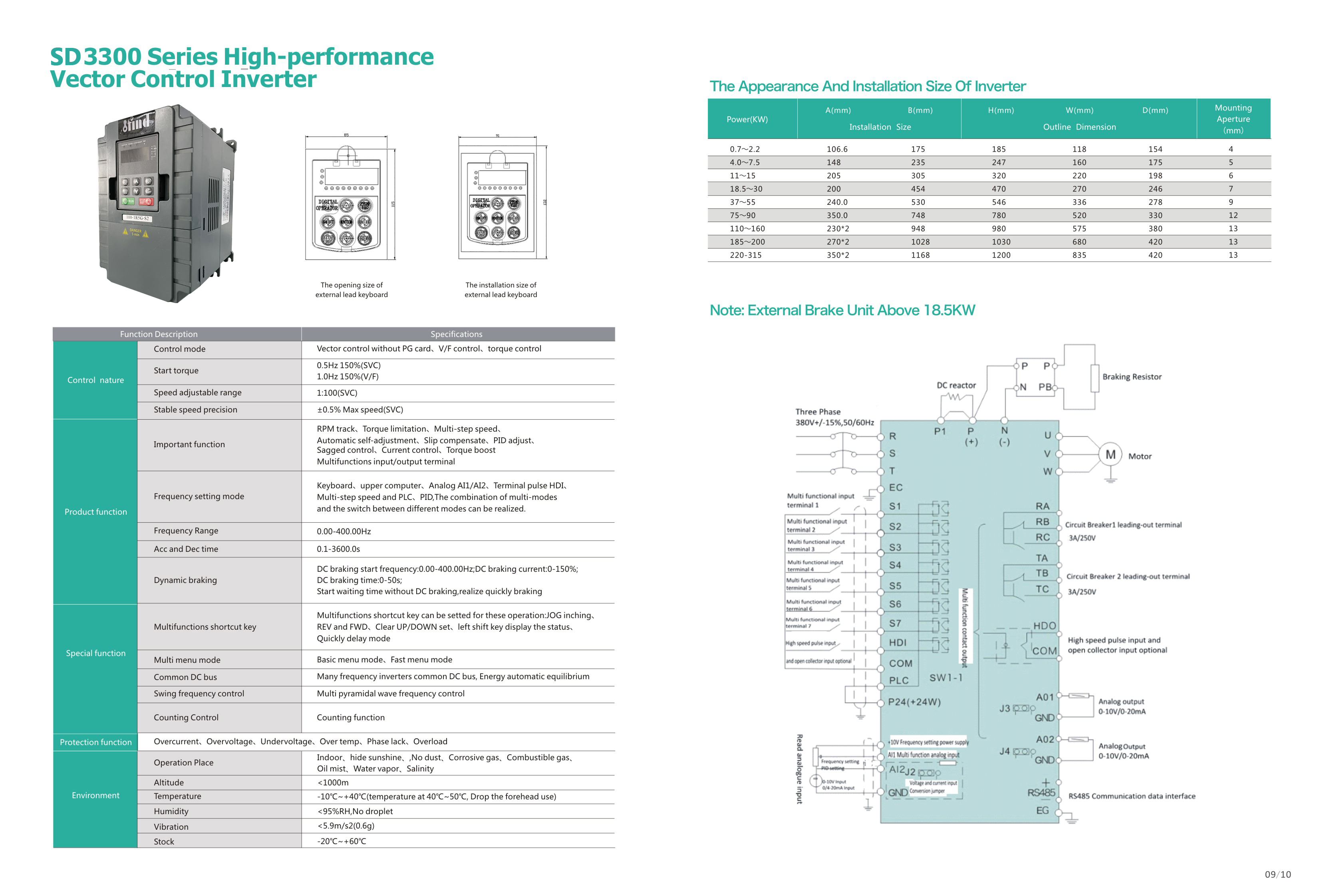

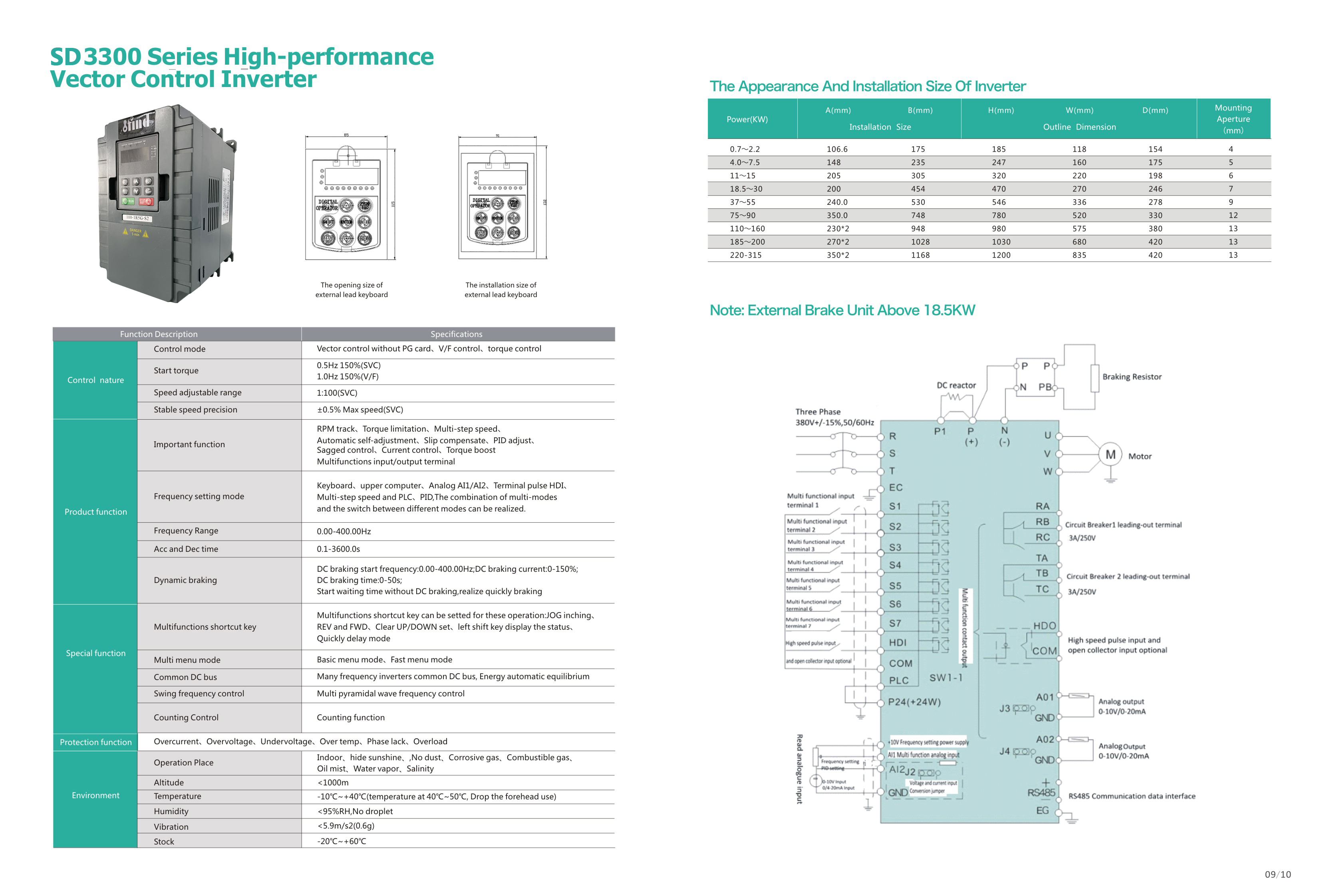

The drawing of China Wholesale High-performance vector inverter

IFIND China Wholesale High-performance vector inverter products high-performance, high-quality and high-power density design, which has significantly improved in ease of use, maintainability, environmental protection, installation space and design standards, and can further optimize the user experience.Integrated with sensor less flux vector control, standard V/F control, 220V or 380V, Rapid dynamic response to quick acceleration/deceleration and rapid braking, Outstanding speed regulation to load fluctuation, Perfect protection such as over temperature, under voltage, over voltage, over load, over current, short circuit protection, Automatic current limiting, voltage limiting to prevent frequent over current/voltage faults in running.