This IFIND 7.5kw 11kw 15kw VFD 3 Phase 400 V Variable Frequency crane inverter is based on a DSP control system, inside PLC,adopts vector control technology, and is combined with various protection methods. It can be used for asynchronous motors to improve their driving performance. It integrates position, speed, and torque control, supports customer secondary development, meets personalized and industry needs, is flexible in application, and has stable performance.Variable frequency inverter applicable occasions:Fans, Pumps, 3-Phase Motors, Machine Tool, Textile, Mining, Chemical, Plastic machinery, Metallurgy, Oil, Woodworking, Pharmaceutical, Ceramics, Paper, Lifting,Printing And Packaging, Air Compressors ,Agricultural Irrigation, etc.

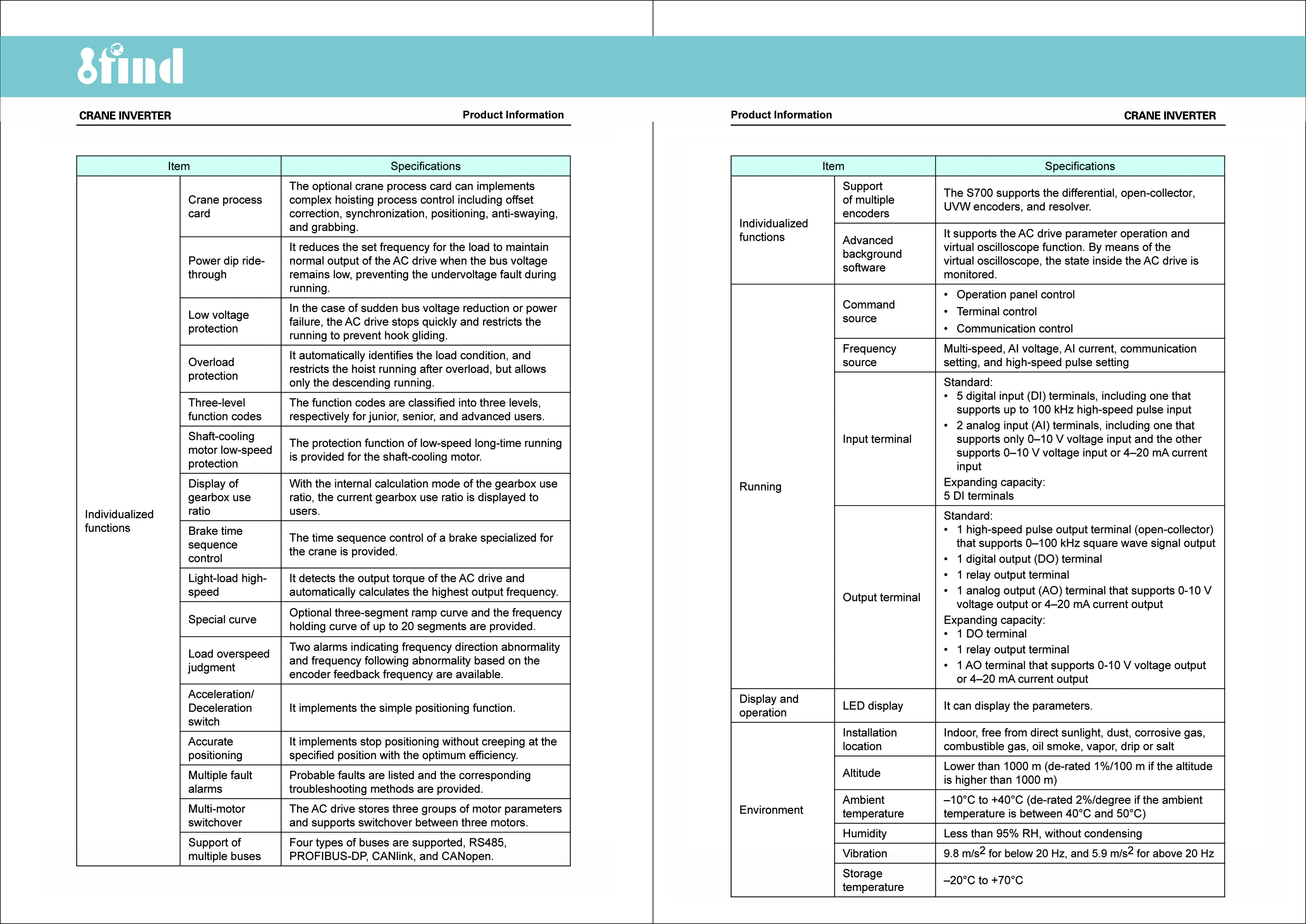

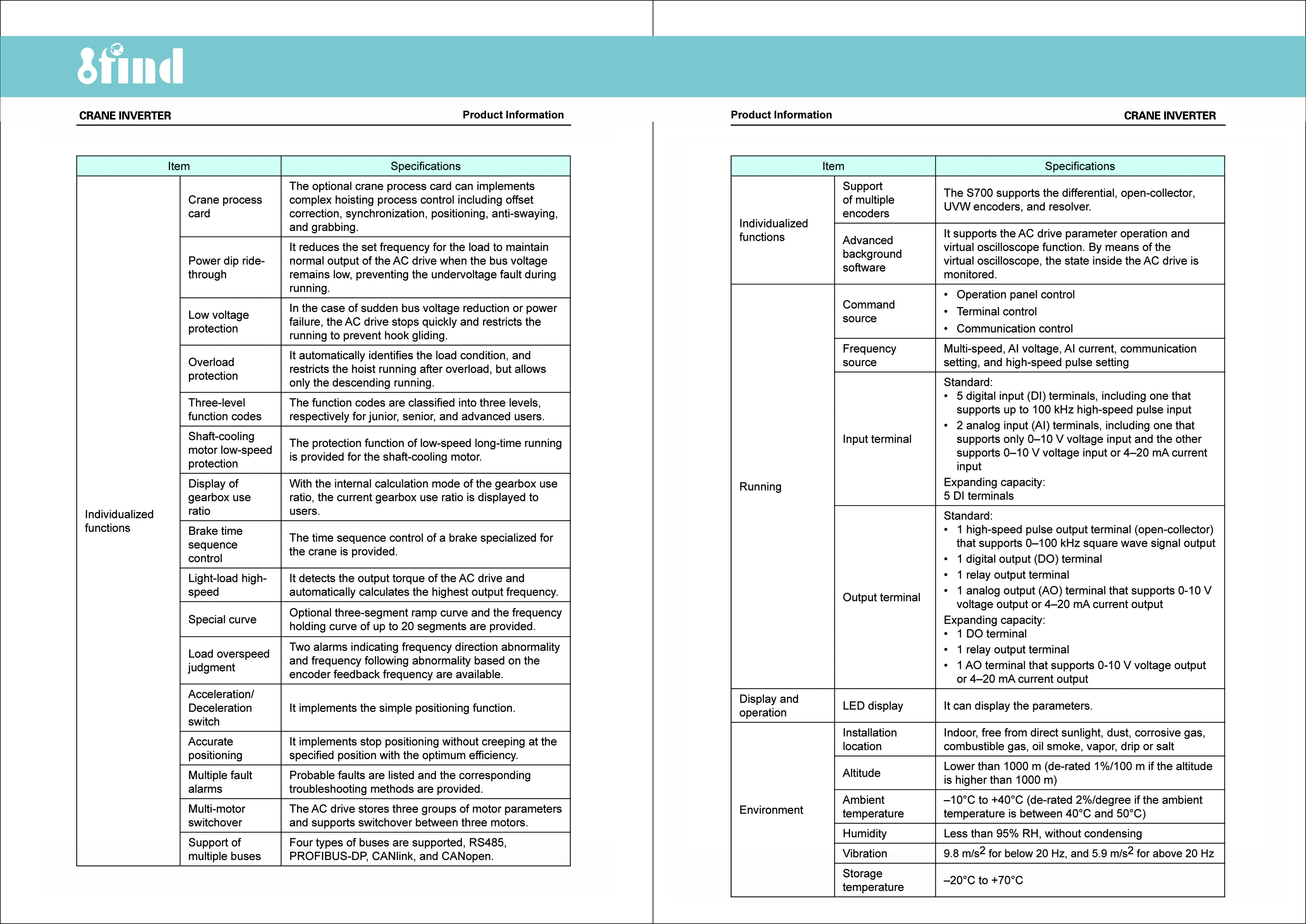

Main functions of 7.5kw 11kw 15kw VFD 3 Phase 400 V Variable Frequency crane inverter

DSP Control System: The use of a Digital Signal Processor (DSP) control system indicates that the VFD is highly advanced, capable of complex calculations and control algorithms for precise motor control.

Inside PLC: The inclusion of a Programmable Logic Controller (PLC) allows for customizable control logic, making the VFD adaptable to various applications and processes.

Vector Control Technology: This technology enables the VFD to control the speed and torque of the motor independently, which is crucial for maintaining performance across different load conditions.

Various Protection Methods: The VFD is equipped with multiple protection features to ensure the safety and longevity of the motor and the VFD itself, such as overcurrent, overvoltage, and thermal protection.

Asynchronous Motor Compatibility: It is designed to work with asynchronous motors, which are common in industrial settings, to enhance their driving performance.

Integrated Control: The VFD integrates control over position, speed, and torque, providing a high level of control over the motor's operation.

Customization and Development Support: It supports secondary development by customers, allowing for customization to meet specific industry needs and personalization

8.The input and output terminals may be freely programmed, so users may combine a variety of operating modes as needed;

9.Equipped with jump frequency control which prevents mechanical resonance and makes the system more stable and reliable;

10.Equipped with instantaneous power failure non-outage capability;

11.Equipped with sleep-wake delay installation capability;

12.Equipped with over-torque detection;chf 100a invt inverter.

13.Variety of maximum frequency setting source options;

14.Equipped with a bidirectional shift key , which enables users to use the shift key to view real-time parameters;

15.Rotation speed tracking re-start function: allowing rotating machinery to be started smoothly and without any shocks.

16.Overload protection ,over current protection

Main advantage:

1. Vector control

2. 0.4-37KW standard built-in brake unit

3. Support common DC bus scheme

4. Support multiple encoding options

5. Integrateed position control

6. Integrated speed control

7. Integrated torque control

8. Closed loop vector control 0HZ 200% torque out

9. Standard RS485 communication control

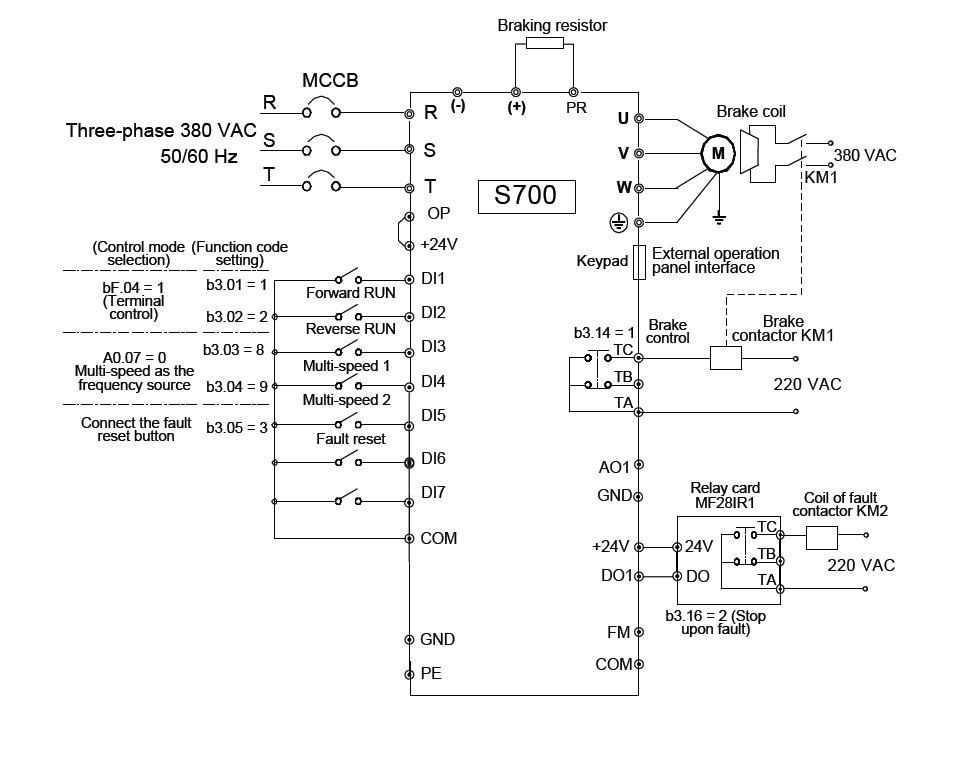

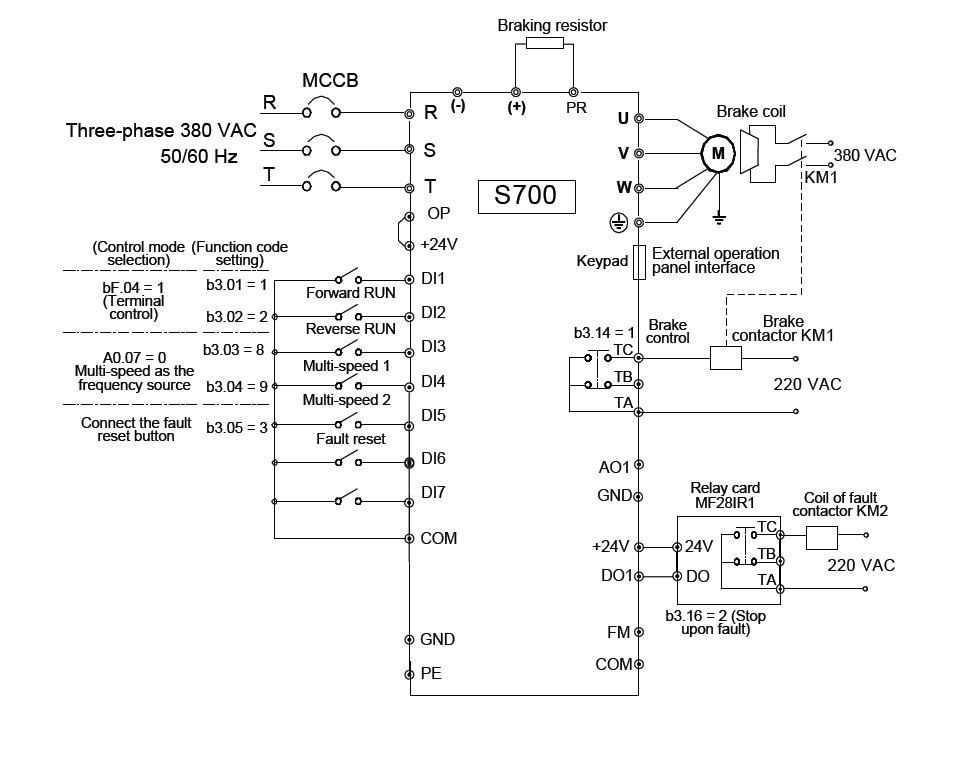

The drawing of High-performance vector crane inverter

IFIND 7.5kw 11kw 15kw VFD 3 Phase 400 V Variable Frequency crane inverter product high-performance, high-quality and high-power density design, which has significantly improved in ease of use, maintainability, environmental protection, installation space and design standards,as the international high-end inverter but also further strengthens the reliability of the productand the adaptability of the environment. Its customized and industrialized design can better meetthe needs of various transmission applications as well.and can further optimize the user experience.Integrated with sensor less flux vector control, standard V/F control, 220V or 380V, Rapid dynamic response to quick acceleration/deceleration and rapid braking, Outstanding speed regulation to load fluctuation, Perfect protection such as over temperature, under voltage, over voltage, over load, over current, short circuit protection, Automatic current limiting, voltage limiting to prevent frequent over current/voltage faults in running.This VFD is a versatile tool that can significantly improve the efficiency and controllability of motor-driven systems across various industries. If you need more information on how to select the right VFD for a specific application.With its high performance, high reliability and high adaptability, this inverter meets the demanding requirements of industrial automation and is the good choice for increasing production efficiency and ensuring equipment safety.